With water reuse, the challenge is no longer public perception, but protecting public health

Looking to Mt. Evans from the hillsides of oak brush and ponderosa pine in Castle Rock, you might get the wrong impression of the city’s water reality. The mountain’s 14,265-foot summit is covered with snow much of the year, suggesting springtime abundance. But only the thin trickle of Plum Creek passes through Castle Rock. Instead, the city of 60,000 relies primarily on wells that draw water from Denver Basin aquifers underfoot. Those aquifers are dropping by about five feet per year. It’s an unsustainable future.

Castle Rock and other water providers in Denver’s South Metro area understand the need to diversify their water supplies. One big piece of that puzzle is water reuse. You’ve heard of locovores, people who favor locally sourced food? This is similar. Call it locoagua. Rather than import water from distant sources, these water-strapped communities can reuse certain water supplies again and again, until they are exhausted. For many communities, it’s the lowest-cost alternative. Given proper treatment, it can be the highest-quality alternative, too.

The concept is relatively new to Colorado. “A lot of people don’t know what reuse is,” says Laura Belanger, president of WateReuse Colorado, an advocacy group that includes many water utilities. “Historically, it has been clumped in with water conservation,” she says. “They are very different things. They have very different challenges.”

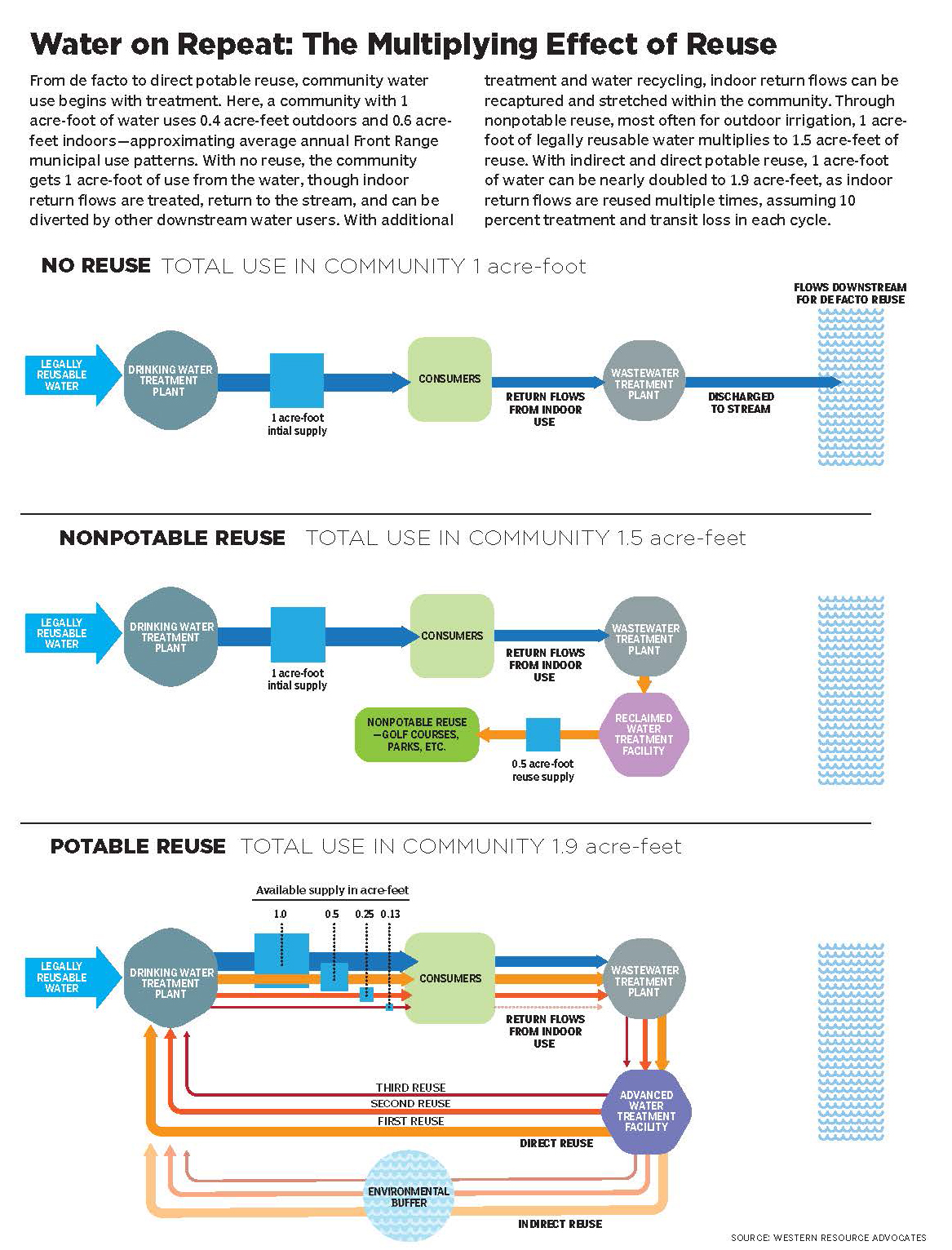

Conservation consists of deliberate strategies to reduce water use, such as irrigating less or choosing efficient landscaping. In reuse, effluent from advanced wastewater treatment plants is captured, pumped uphill to the same jurisdiction, then used again. Colorado’s Water Plan, established in 2015, calls both critical to addressing future water demands posed by population growth. In the last several years, many water utilities have started talking about reuse, says Belanger. The discussion, she adds, “is going to be advanced first by the folks who have the tightest water supplies.”

From de facto to deliberate

Water gets used repeatedly in Colorado. Along the South Platte River, for example, much of the water diverted to farms comes from river flows that consist primarily of discharges from upstream wastewater treatment plants. A few towns and cities also tap a river that consists primarily of treated effluent. This is called de facto reuse. Even well-heeled Beaver Creek Resort, about as close to the headwaters as you can get, gets water from the Eagle River downstream from the wastewater treatment plants of Vail and Red Cliff.

Deliberately reclaimed water is different. Colorado Springs and Fort Carson embraced this practice in the 1960s. Now 25 jurisdictions across Colorado make use of reclaimed water for nonpotable uses, mostly to irrigate parks, golf courses, and other landscaping.

Applications of reuse have expanded in the 21st century. Two agencies, Aurora Water and Parker Water and Sanitation District, use indirect potable reuse. As the name suggests, drinking water is derived from wastewater. Advanced treatment occurs at both the wastewater discharge and at the water treatment plant, but with an environmental buffer. The treated wastewater is introduced into a river, an aquifer or a reservoir before being tapped again. The buffer may provide an additional level of natural treatment, but it also fosters a public perception of disconnect in this circle of blue.

Fear of drought induced Aurora’s Prairie Waters Project, Colorado’s first indirect potable reuse system. After a parched 2002 and a dismal start to 2003, Aurora reservoirs were down to 26 percent of capacity. A giant snowstorm averted disaster, but chastened city officials grabbed the easiest available water: their own once-used supply. The water is collected near Brighton, from wells along the South Platte River. The wells draw water from an alluvium, an aquifer connected directly to the river. For much of the year, the river here consists almost completely of Metropolitan Wastewater Treatment Plant releases. The plant, 20 miles upstream, processes wastewater for 1.8 million people in the Denver area, including those in Aurora. Because the water is drawn from downstream wells, not directly from the wastewater treatment plant’s outlet, the system is called indirect potable reuse.

From Brighton, the water is pumped 1,000 vertical feet and 35 miles upstream to the Binney Water Treatment Plant. There, the water is treated biologically, chemically, and with other technologies, then mixed with water imported from the headwaters of both the South Platte and Eagle rivers. Aurora calls this its “mountain water.” It’s not that the reuse water is any less pure. Rather, this mixing ensures that all Aurora water tastes the same.

Aurora Water tiptoed through this Colorado debut. “When we opened Prairie Waters, we were very careful not to call it a reuse system,” says spokesperson Greg Baker. “We were telling people that we were recapturing water and left it to them to put two and two together.” Now, Aurora talks openly about its water reuse. The response of the public has been that there should be more reuse, says Baker. The lesson, he says: “Don’t project your own fears.”

Overcoming the yuck factor

You can’t blame Aurora for being careful. In the 1990s, water reuse projects for Los Angeles and San Diego were derided as “toilet to tap” and then defeated. A survey commissioned by the San Diego Water Authority in 2004 found that 63 percent of respondents opposed reuse.

Drought and public information campaigns have dissolved that opposition in California and elsewhere. “As ‘Yuck Factor’ Subsides, Treated Wastewater Flows From Taps,” the New York Times reported in a 2012 headline. With California and Florida leading the way, the United States now has hundreds of reclaimed or recycled water applications. Like that of Aurora and now Parker, nearly all are indirect potable reuse. Only one U.S. water utility, at Big Spring, Texas, now employs a closed-loop system, called direct potable reuse. Another Texas city, Wichita Falls, built a direct potable reuse system as a temporary emergency drought measure, authorized for only six-month periods until indirect potable reuse was possible again. That system was decommissioned once drought subsided—its temporary pipeline, initially used to pipe lake water, was restored to its original purpose as soon as the lake was full.

Decades ago, Denver Water began experimenting with direct potable reuse when it entered into a cooperative agreement with the U.S. Environmental Protection Agency (EPA) to demonstrate the feasibility of direct potable reuse. It operated an experimental direct potable reuse plant from 1985 to 1990, leading the way for the industry at the time. Myron Nealey, a senior hydraulic engineer for Denver Water who worked at the plant, says tests showed “no statistical difference” in quality between water produced by the plant and Denver Water’s other sources. But the water was expensive to produce because of the multi-barrier approach to remove contaminants, and Denver Water was still intent on developing more raw water sources. Although Denver Water didn’t pursue continued direct potable reuse at the time, Nealey says he sees support growing for indirect potable reuse and, perhaps eventually, direct potable use. Now Denver Water is considering continued reuse research at a water innovation center in conjunction with Colorado State University as part of the redeveloped National Western Complex in Denver.

In Castle Rock, town council members are supportive of long-term plans to reuse all of the town’s legally reusable supplies to the greatest extent possible. Still, Castle Rock Water continues to evaluate multiple options for reuse. The primary plan is to create an indirect potable reuse system, which would recapture treated wastewater as close as 100 yards downstream from its release and pump it uphill to the Plum Creek Water Purification Facility, where additional processes would treat the water to high drinking water standards. Water utility manager Mark Marlowe sees a thin distinction between indirect potable and direct potable reuse. Speaking at the 2016 Colorado Water Congress Summer Conference, Marlowe said he favors a more generic description of reuse: “Just because water goes into a creek or reservoir for a short or intermediate period of time before it’s recovered or reused doesn’t necessarily make it better in quality.” What matters, he says, is that the “water is treated in ways that remove what needs to be removed.”

In 2015, Parker became the second water provider in Colorado to employ indirect potable reuse. The water is captured after treatment and pumped uphill to Rueter-Hess Reservoir. The reservoir provides an environmental buffer, but it also provides storage so the water can be reused as needed. “Those of us in the West who don’t have the massive supplies of water have been forced to get more creative,” explains Ron Redd, manager of Parker Water and Sanitation.

Yes, Parker could seek new supplies far afield. The town does own a farm 151 miles away, downstream from Sterling, whose water it plans to eventually use through exchange, allowing pumping from Fort Morgan, 60 miles closer. But it isn’t pursuing distant rivers, such as the Yampa or the Green. Reuse, says Redd, is cheaper and politically a lot easier, too.

The math is also compelling. Parker estimates it needs 9,000 to 10,000 acre-feet of water per year to meet demand at buildout. Reuse can represent 7,000 acre-feet per year. The water is pumped six miles upstream, which cost $1.30 in electricity per thousand gallons of water last year. To buy water from farms between Denver and Greeley would require pumping too, and a purchase price of $25,000 to $30,000 an acre-foot. Add that to the pumping costs and pretty soon the sum reaches the millions. “If we cannot recapture [our water], it would extract $175 million out of this community,” says Redd.

As the law protects and binds us

Water under Colorado law cannot be reused in most cases. After a first use, it must flow downstream to other adjudicated users who have a right to that water. Exceptions include transbasin diversions, which convey water from one river basin to another. These can be reused to “extinction.” At Aurora, 27.6 percent of the city’s water is imported from the Colorado River Basin and 22.8 percent from the Arkansas. Both sources are reusable.

The Colorado-Big Thompson (C-BT) Project is uniquely different. Water from that conveyance can only be used once. That’s because the Northern Colorado Water Conservancy District pledged to the federal government that water would be allowed to flow downstream after first use. Northern Water public information officer Brian Werner says that was a selling point when organizers were trying to persuade downstream farmers around Fort Morgan and Sterling to join the district. Windy Gap water, despite being transported through C-BT infrastructure, can be reused. Water pumped from Denver Basin aquifers by Castle Rock, Parker and other South Metro water providers can also be reused repeatedly because it’s considered non-tributary, or disconnected from surface streams. However, water pumped from aquifers tributary to rivers cannot be reused unless, as in the case of Aurora, it’s the wastewater that originated as imported water.

Purple-pipe systems that deliver reclaimed water for non-domestic use are relatively common in Colorado. Begun in 2004, Denver Water’s network of 68 miles of purple pipe delivers nonpotable water to 34 parks, nine schools, five golf courses, and the Denver Zoo. But such systems have so far fallen short.

One problem of purple-pipe reuse systems is that laying redundant pipes to distribute nonpotable water is expensive. Nonpotable uses are also limited primarily to outdoor landscaping. As such, there is no demand for five or six months each year, which means less revenue to defray expensive infrastructure. What’s needed are year-round customers, explains Allegra da Silva, a supervising engineer with consulting firm MWH.

A young gardener harvests greens irrigated with Denver’s treated drinking water at a Denver Urban Gardens (DUG) community garden in the Lincoln Park neighborhood. DUG is a proponent of changing Colorado’s Regulation 84, which prohibits the use of nonpotable reuse water on gardens or farms that produce edible food. Courtesy: Denver Urban Gardens

Reuse advocates would also like state regulations amended. Colorado’s Regulation 84 only allows use of reclaimed water for non-domestic outdoor uses. Use is not allowed on gardens or farms that produce edible food. Denver Urban Gardens (DUG) has 157 community gardens in metropolitan Denver, of which 49 are on school grounds. DUG wants to help foster healthy eating habits at an early age through the positive experience of tending and harvesting produce. Shannon Spurlock, community initiatives director for DUG, cites South High School. “(They) would like to have a community garden, but the campus is being switched over to reclaimed [water], so because edible crops or food crops are not allowable, that precludes this opportunity.”

Denver Water has appealed to the Colorado Water Quality Control Commission, a decision-making body within the Colorado Department of Public Health and Environment (CDPHE), to revise Regulation 84. It would like to see the reclaimed nonpotable water allowed on gardens but also in toilets and urinals. This would expand the market for its underutilized recycled water.

What is the basis for CDPHE’s regulation? The agency reasons that water for landscaping is likely to have little direct contact with humans. But growing food? Very likely. With indoor use, even in bathrooms, contact can also be expected. Contact means more exposure to pathogens and increased risk of disease. “Using reclaimed water for edible crops is really very, very different for us, because there is so much more potential for human contact,” says Lillian Gonzales, permits unit manager in CDPHE’s Clean Water Program. The burden of proof falls on proponents like Denver Urban Gardens or WateReuse Colorado to provide evidence that there is no risk from human contact. If we want to add uses like irrigating edible crops, we may need more stringent water treatment requirements to protect public health, Gonzales says.

Moving forward

Changing regulations governing water quality is not done lightly. An April 2016 memo from CDPHE says that changes in Regulation 84 are warranted, but lays out an initial list of concerns that would need to be addressed before the law could be revised. These include, for example, antibiotic-resistant genes and bacteria in reclaimed water and also a pathogen called Legionella. The memo also worries about the accumulation of salt when water is recycled again and again.

Direct potable reuse is uncharted territory. No such regulations exist anywhere in the United States. The EPA has not issued guidelines. Texas, in authorizing the plants at Big Spring and Wichita Falls, did so on a case-by-case basis. California’s State Water Resources Control Board submitted a report to legislators in September 2016 stating that the development of direct potable reuse criteria in the state is feasible, but there are no plans to-date to start that process.

Colorado neither expressly bans nor authorizes direct potable reuse. Water utilities would like direction, and soon. Clear requirements for protecting public health would enable the utilities to avoid the added cost of redesign if initial plans don’t meet standards that eventually develop, or conversely, over-design, costing communities more than necessary. Trying to implement a site-specific direct potable reuse system in Colorado to satisfy any potential concerns would likely take considerable time and money, Marlowe says.

A $303,000 effort to facilitate the safe and effective adoption of direct potable reuse has been launched by WateReuse Colorado with aid from the state, water utilities and several basin roundtables. The project has three goals: First, synthesize what other states are doing, define risk factors, and draft a framework to develop regulations in Colorado. Second, advance public understanding and support for potable reuse. Third, help utilities evaluate potable reuse projects. The project consultant, Carollo Engineers, will convene workgroups consisting of water utilities, state agencies and nonprofits. When complete, all project materials and products will be publicly available.

Treatment technology is not really the issue. Several treatments, such as those used at Aurora’s cutting-edge Binney Plant, can remove pathogens and other things that shouldn’t be consumed. A sticky issue for Colorado, though, are salts, which over time build up in water reused repeatedly. Salt can be removed by reverse osmosis technology, but disposing brine in deep wells, such as those once used to extract oil, requires pressure and hence energy. Injections could also create risks of geological instability. Oklahoma’s recent earthquakes have been linked to deep-well injections. For that matter, metropolitan Denver in the 1960s had earthquakes linked to injections at the Rocky Mountain Arsenal. Brine injection also wastes water.

An $820,000 study funded by the Colorado Water Conservation Board and state water providers focused on whether brine can be further concentrated to maximize the amount of water for reuse and minimize disposal costs. The study, published after peer review in 2014, said yes, technology can wring almost all water out of brine. The technology, however, is complex and more development is needed before it is adopted by utilities. Until that happens, extracting the salts and recycling them, for purposes such as to deice roads or as a component in wallboard, is a goal but unattainable today.

Defining acceptable risk is a critical challenge. For example, what level of monitoring should be required to ensure that traditional pathogens and also emerging contaminants are removed? “We have to take all of that very, very seriously if we try to develop wastewater into a direct drinking water source,” says Philip Brandhuber of consulting firm HDR.

Maintaining public trust is crucial. “All it takes is one sick child,” said Patricia Mulroy, the former general manager for the Southern Nevada Water Authority, at the Western Water Symposium in July 2016. Or, for that matter, one Flint, Michigan.

Yet requirements can be so stringent that direct potable reuse becomes impractical, says John Rehring, who is directing the Carollo study. “We can require every process known to man, to be really, really sure, but then nobody will do it,” he says. From his research, Rehring says public perception is just as important as the technology itself. Water providers must be transparent, he says, but must also court the public. They must make the case that direct potable reuse is safe.

CDPHE is on board to help but it lacks the resources to take the lead in developing the regulations. Somebody else must pay the bill. But the agency will help in seeking public acceptance. “That’s probably the biggest issue,” says Tyson Ingels, lead drinking water engineer in the agency’s Safe Drinking Water Program. “We would stand beside a water system in their campaign to achieve public acceptances, but it would not be ours to lead.”

There’s no emergency to incite rush. Deliberate steps are being taken to weigh the risks, define the oversight needed to reduce risks, and engage the public. Downstream water users are part of that public, as Denver Water CEO Jim Lochhead said in July, and impacts of reuse in metropolitan Denver to downstream agriculture must be considered. “We have the legal right to consume all of our imported water, but it’s not the right thing to do,” he said. “We need to sit down and have that conversation.”

Can the phrase toilet-to-tap be used? It will, inevitably, if Colorado gets a direct potable reuse project. It’s misleading, say those engaged in the issue of reuse, but they don’t recoil now when they hear it.

“There is a saying that water should be judged by its quality, not by its history,” says Rehring. “That speaks to that.”

Print

Print